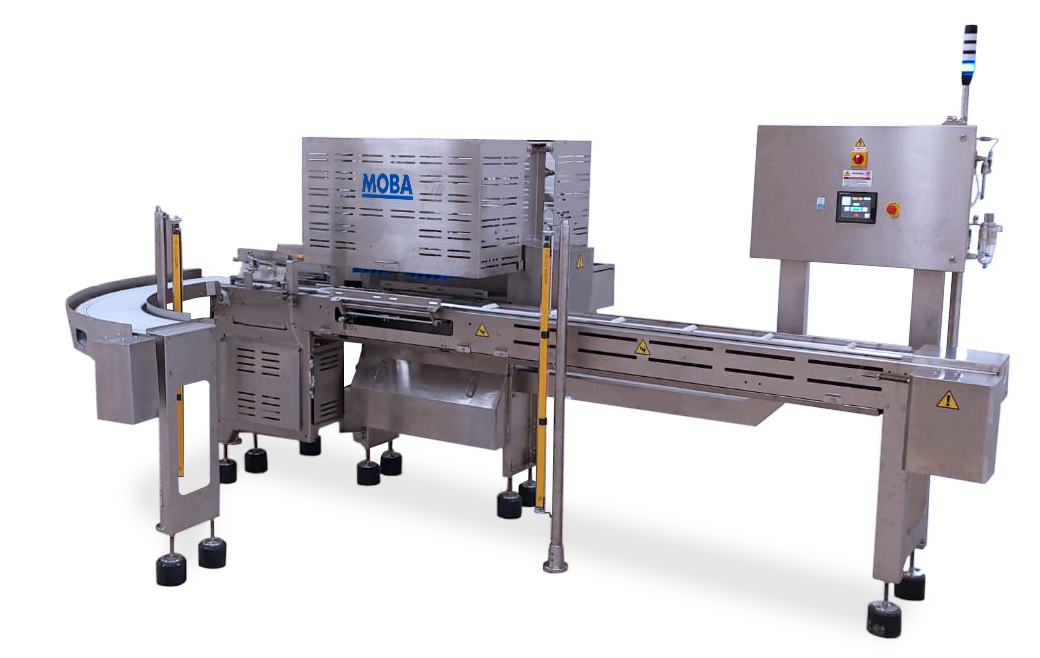

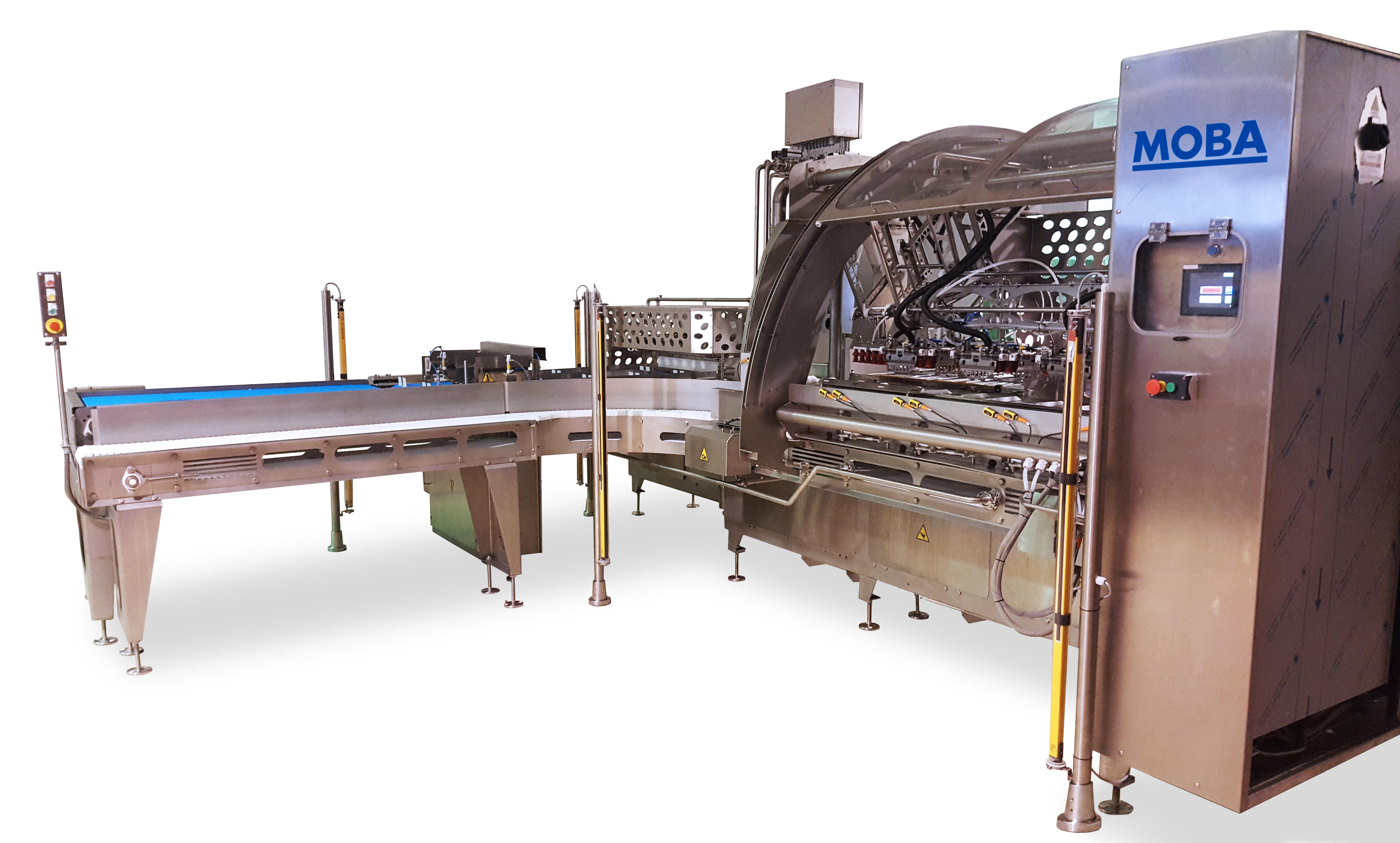

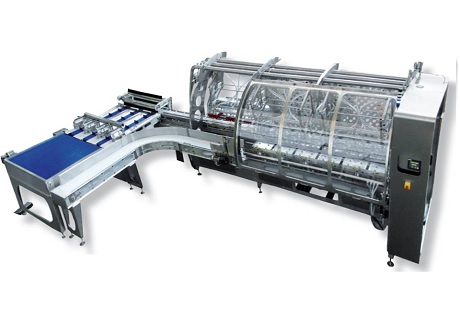

The Forta ET is designed with cost efficiency in mind and especially focuses on basic grading functionality with a hygienic stainless steel design and a small footprint in combination with semi-automatic or manual candling of eggs. The Forta ET is available in two capacities: the Forta ET60 (21,600 eggs/hour) and the Forta ET100 (36,000 eggs/hour).

The machine incorporates Moba’s individual egg handling concept. This means that from the time the eggs arrive on the rollers at the infeed section all the way down to the consumer pack any contact between eggs is avoided to reduce cross contamination and keep track of every individual egg. All of today’s market requirements regarding hygiene such as a washable infeed and packing lanes are met, and the packer parts are removable for Cleaning Out of Place. To save valuable spacing, the Forta ET can be equipped with short automatic packing lanes, which makes the machine easy to integrate into your plant due to its unique small footprint. The extremely short and robust infeed combined with the short automatic packing lanes makes the ET the perfect fit for your operation.