This system will not only remove leakers, but also dirty eggs before touching the next roller section in the so called ‘Multi drum’. By doing so, ‘clean’ and ‘dirty’ areas can be defined. This method removes dirty eggs in the earliest possible stage without the need to pass unnecessary roller sections, egg dryer, UV system or any other downstream technology. For now, the Multi Outlet is only available for the Omnia PX700. Contact your ASM for further information.

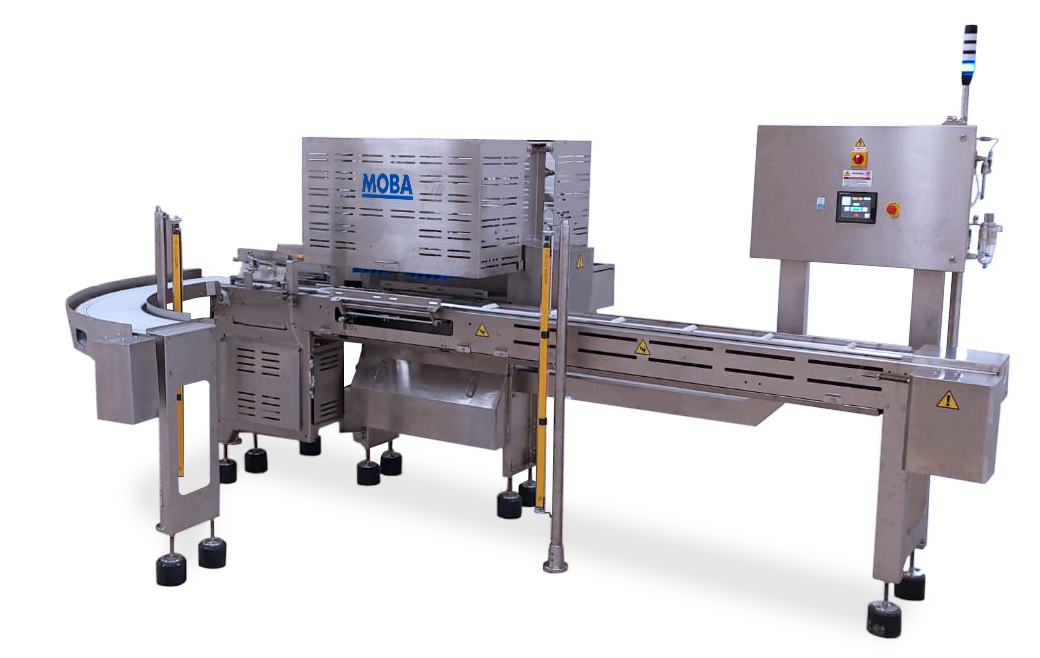

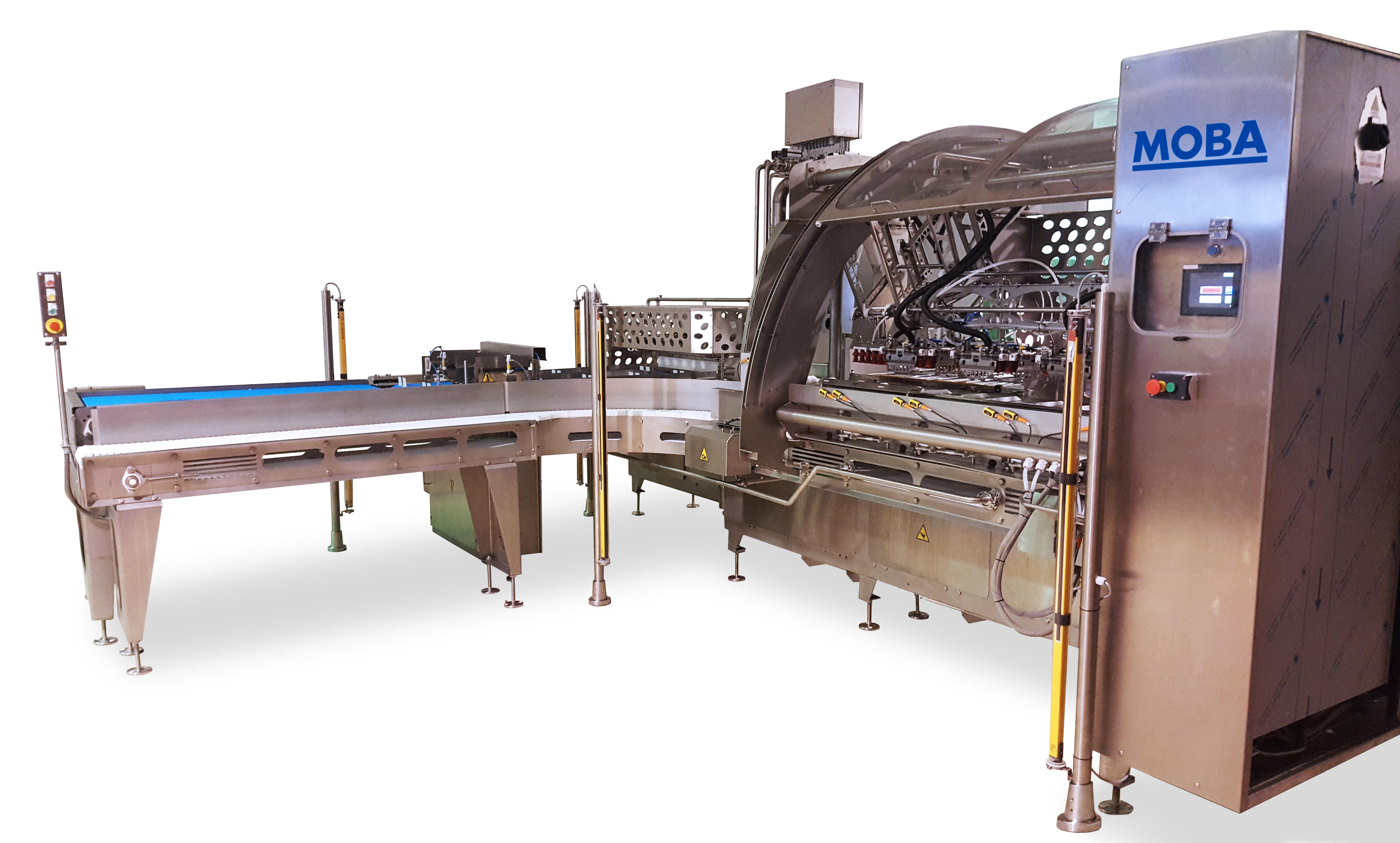

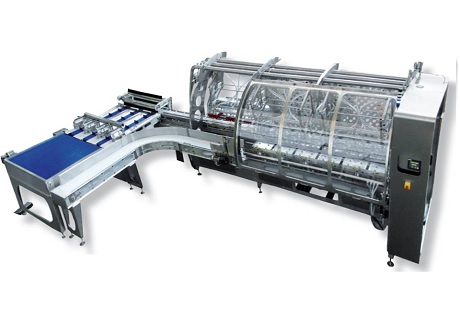

Multi Outlet

The Multi Outlet system will not only remove leakers, but also dirty eggs before touching the next roller section in the so called ‘Multi drum’.

Product Information

Specifications

Downloads

Videos

Related solutions